|

The SITA FoamTester analyses the characteristics of surfactant-containing liquids easy, fast and precise with automated measuring sequences.

• Fully automated foam analysis • Precise reproducible foaming • Measuring foam and liquid volume • Analysing foam structure • Automated cleaning

|

|

|||||

Analysing foam parameters, Controlling surfactant effects

The new generation SITA FoamTester

20 years of experience meets the needs of innovative foam testing

Overview of automated SITA foam testing

| The automated foam testing with the SITA FoamTester offers an efficient evaluation of surfactant containing liquids to analyse numerous influence factors on the foaming behaviour. | ||

|

Functionial components of the SITA FoamTester |

||

| Development and application tasks can be easily simulated by the comfortable sample handling with the temperature-controlled sample reservoir and measuring vessel, by the automated cleaning system as well as by the fast and free creation of experiments in the software. | ||

|

||

|

Benefits of automated foam testing |

||

| • | Autonomous repetition of test runs without intervention by the user | |

| • | Immediate statements about the reproducibility | |

| • | Fast and easy screening of test and sample parameters | |

Foam creation

|

Foaming of the sample by stirring with the proven SITA method |

||

| • |

Use of the established SITA standard stirring disc which has been developed for a reproducible and application-oriented foam creation under mechanical pressure

|

|

| • |

Removable measuring vessel with stirring unit

|

|

| • |

Differentiation of various sample preparations by adaptable stirring parameters: speed, duration, acceleration, direction, intervals |

|

Measuring principle

|

Two optical, contactless measuring systems for the determination of foam and liquid volume as well as foam structure |

|||

| • |

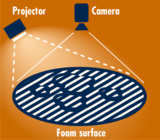

Measuring system Foam Surface Scanner Determination of the foam topography and the resultant total volume by the structured-light method which reproduces the topography of the foam three-dimensionally by using projection and detection of various stripe patterns |

||

|

|

|

|

| • |

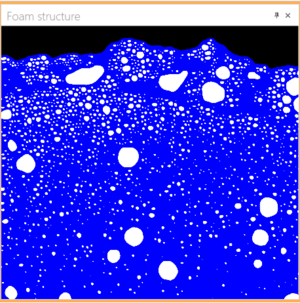

Measuring system Foam Interface Scanner Determination of the liquid level and the foam structure in the measuring vessel by using the total reflexion with a camera system including a line scan camera and an integrated lightning assembly |

||

|

|

|

|

|

Recording of the foam structure over the range |

|||

| • | Combination of both measuring systems for the automatic determination of the foam volume | ||

| • | Analysis of clear and cloudy liquids | ||

| • | All measurements in the same measuring vessel, connected to the thermal circuit | ||

Analyse foam and understand foaming

|

||

| • | Convenient evaluation of measuring data with the software SITA-FoamLab in the office | |

| • |

Complete transparency of the measuring progress and the results by intuitive visualisation |

|

| • | Analysis of the slope and the resulting volume during foam formation | |

|

||

| • | Analysis of the foam decay and the drainage | |

|

||

| • | Analysis of bubble sizes and shapes in the foam structure | |

|

||

| • | Comprehensive characterising of foam and foaming | |

| - | By the determination of further parameters such as half-life period and foam density | |

| - | By the individual height-dependent evaluation of foam structure parameters such as average bubble size or circularity index | |

| - | By tracking time dependent changes in the foam structure | |

| - | Flexible comparison by clear display of different measuring sequences | |

| - |

Easy export of data and results for documentation

|

|

Applications

|

Optimisation of surfactant containing products in |

||

| • | Product Development | |

| • | Raw material development and selection | |

| • | Product processing and application | |

| • |

Quality and process assurance |

|

|

Application examples |

||

|

Cosmetics |

||

| • | Influence of the formulation and raw materials on foaming behavior | |

| • | Foam stability of toothpaste and foam baths | |

| • |

Foam structure as a reference point for user perception |

|

|

Cleaning agents |

||

| • | Influence of temperature on the foaming of spray cleaners | |

| • |

Influence of contaminations on the foaming in cleaning baths |

|

|

Cooling lubricants |

||

| • | Influence of water hardness on aging process | |

| • | Durability of defoamers | |

| • |

Optimisation of the filtration process to prevent foaming |

|

|

Inks, paints and coatings |

||

| • |

Effectiveness of defoamers |

|

|

Liquid processing industry |

||

| • |

Foaming behaviour of flow suspension in paper industry |

|

| • | Recipe optimisation to reduce foaming in bottle filling of beverages | |

| • | Adjustment of foaming production auxiliaries in textile manufacturing | |

| • |

Foaming effects of polymers in plastic production |

|

Technical data

| Foam creation |

|

| Recommended sample volume | (200 ... 500) ml |

| Usable measuring vessel volume |

1,500 ml (incl. foam) Dimensions: |

| Capacity of sample reservoir |

2,000 ml |

| Sample tempering of measuring vessel and sample reservoir |

(0 ... 60) °C using a optional thermostat |

| Stirring speed | (0 ... 2,000) U/min (bidirectional) |

| Adjustable stirring programs | speed, duration, direction, acceleration |

| Analysis of foam volume (foam creation and decay) | |

| Measurement values |

total volume, foam volume, liquid volume |

| Evaluated parameters | max. foam volume, foam half-life, flash foam |

| Measuring range total volume | (0 ... 1,500) ml; resolution 1 ml |

| Measuring range liquid volume |

(0 ... 500) ml; resolution 1 ml |

| Analysis of foam structure |

|

| Parameters | number of bubbles, bubble size distribution, average bubble diameter, circularity index |

| Evaluation area | height 130 mm width 50 mm |

| Resolution | 3,200 dpi |

| General data | |

| Rinse connection | 3/4“ (2 ... 6) bar |

| Operating temperature | (10 ... 40) °C |

| Power supply | (100 ... 240) V / (50 ... 60) Hz, 300 W |

| Dimensions (HxWxD) | (770 x 450 x 305) mm |

| Weight | approx. 35 kg |

| PC interface |

Ethernet

|

Optional: External laboratory devices for sample conditioning

|

|

| • | Extension of experiments by additional functions for sample conditioning |

| • |

Automatic integration and direct control within the test sequence

|

|

Automatic dispenser CAT Contiburette μ10D |

||

|

for the dosage of liquids Resolution: 10 µl Dosing speed: 0,2 - 20 ml/min |

|

|

|

Thermostat Lauda ECO RE 415S |

||

|

for cooling and heating of sample liquids Temperature range: (-15...200) °C Ambient temerature range: (5 ... 40) °C |

|

|

|

Thermostat Lauda ECO E4S |

||

|

for heating of sample liquids Temperature range: (room temperature...200) °C Ambient temerature range: (5 ... 40) °C |

|

|

Previous model SITA foam tester R-2000

|

The previous model SITA foam tester R-2000 is no longer available. If you have any questions concerning your existing device, please contact us directly. |

|

|

| The market launch of the SITA FoamTester is supported within the scope of the German development programme "Market launch of innovative products and product design". |